Jubilant has a wide product portfolio of Ester Gum grades for industrial applications. Ester Gum is a thermoplastic material, which are available in the form of flakes. The product is manufactured at a modern “state of the art“ manufacturing facility at Gajraula (UP). The products as well as the manufacturing facilities are accredited with ISO 9001, ISO 14001 and OHSAS 18001 certifications. Jubilant is now expanding its portfolio of products in order to have a wider offering for various industrial applications. The company has a strong in-house R&D capability to develop products & solutions to meet specific needs of customers and applications.

Chiclet shaped Hot Melt for Book Binding

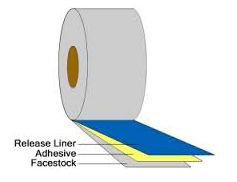

Pressure Sensitive Adhesive

Cosmetics

Graphic Arts

Specifications

|

S. No. |

Product |

Specification |

Application Areas |

Details Application |

|

1 |

Glycerol Ester of Gum Rosin – Non Food application |

Softening Point (R & B) 90 ± 2°C |

Adhesives |

Tackifier Resin for various types of adhesives |

|

Colour : Max. 8 G |

Hot Melt Adhesives & Sealants |

|||

|

Acid Value : Below 9 |

Tape Label & PSA |

|||

|

2 |

Penta Ester Gum |

Softening Point (R & B): 110 ± 2°C |

Adhesive |

Tackifier Resin for various types of adhesives |

|

Colour : Max 12 G |

Road Marking Paints & Tape Label & PSA |

|||

|

Acid Value : Max 20 |

Hot Melt Adhesives & Sealants |

|||

|

3 |

Glycerin ester of rosin modified with maleic anhydride |

Softening Point (R & B): 105 ± 2°C |

Paint & Ink |

Ink, Paint, Varnishes, Sealers |

|

Colour : Max. 8 G |

Formulated specially for use in toluene-acetone blends |

|||

|

Acid Value: 30 to 45 |

Can be used in formulations with nitrocellulose lacquers |

|||

|

4 |

Maleic Adduct of Gum Rosin |

Softening Point (Drop Point):Min 140± 2 °C |

Printing Ink |

Manufacture of Printing Inks & Pigment resination |

|

Colour : Max. 8 G |

||||

|

Acid Value : 260 to 290 |